New developments in space technology have brought about innovative solutions for our planet’s sustainability. PNEUMO PLANET is one such concept that demonstrates this excellently.

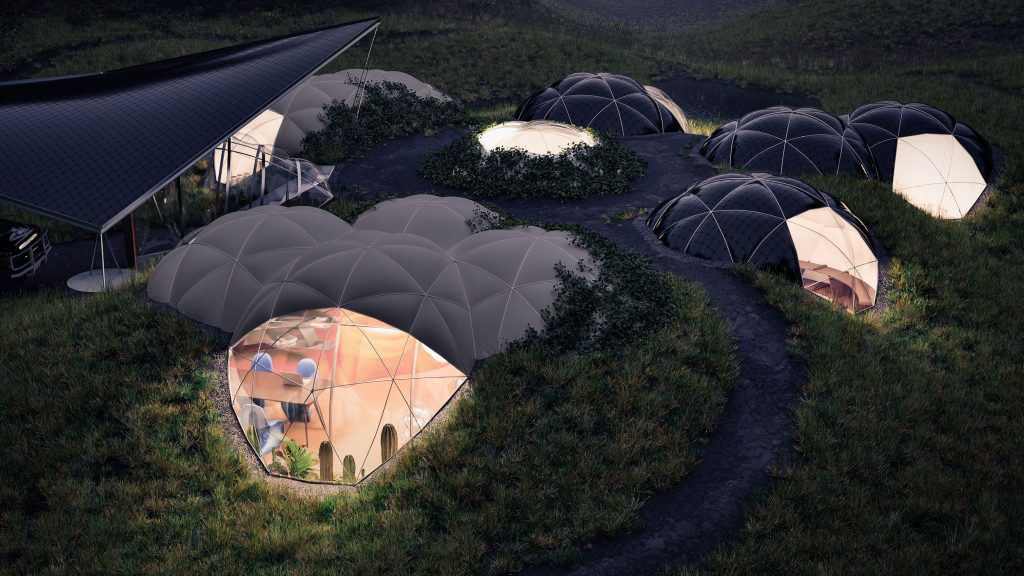

PNEUMO PLANET EARTHHOUSE is a prefabricated house that derives from PNEUMO PLANET Moon Habitat, consisting of inflatable room modules that are partly underground.

It combines the advantage of a low mass ultra-light inflatable membrane structure with the mass and thermal properties of surrounding soil:

PNEUMO PLANET EARTHHOUSE:

Space Technology applied on Earth to preserve our ecological system.

Benefits of PNEUMO PLANET Earthhouse:

- Energy-efficient and minimizes the use of resources

- Requires no energy to be heated in winter or cooled in summer

- Consumes minimal grassland, having no negative impact on nature and wild life

- Is approximately 1000€ cheaper per m2 to construct compared to a conventional house made of bricks and concrete

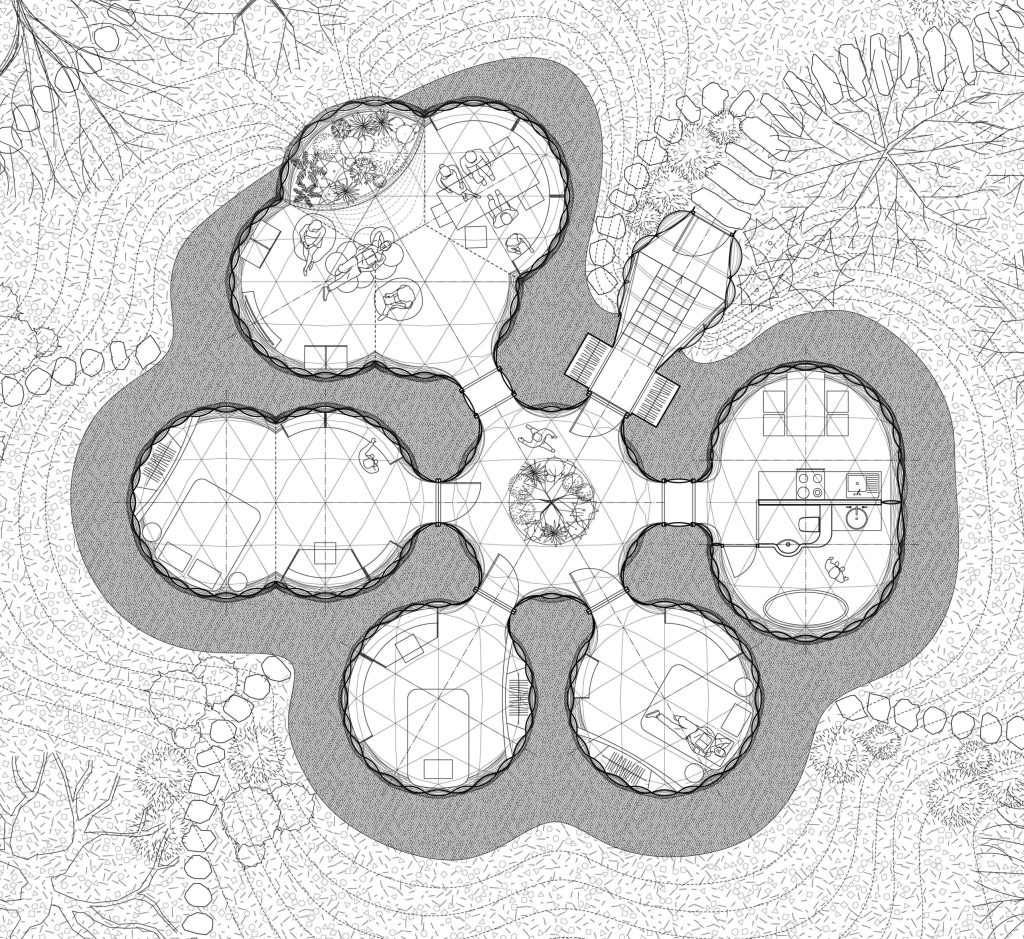

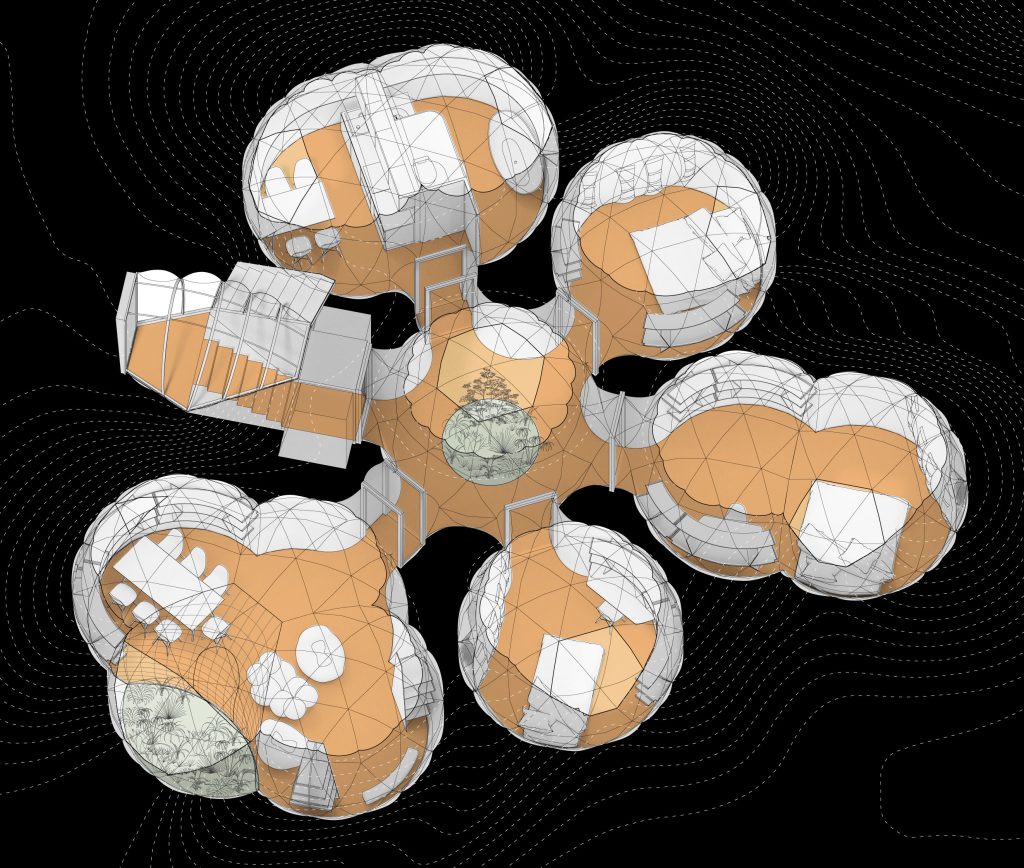

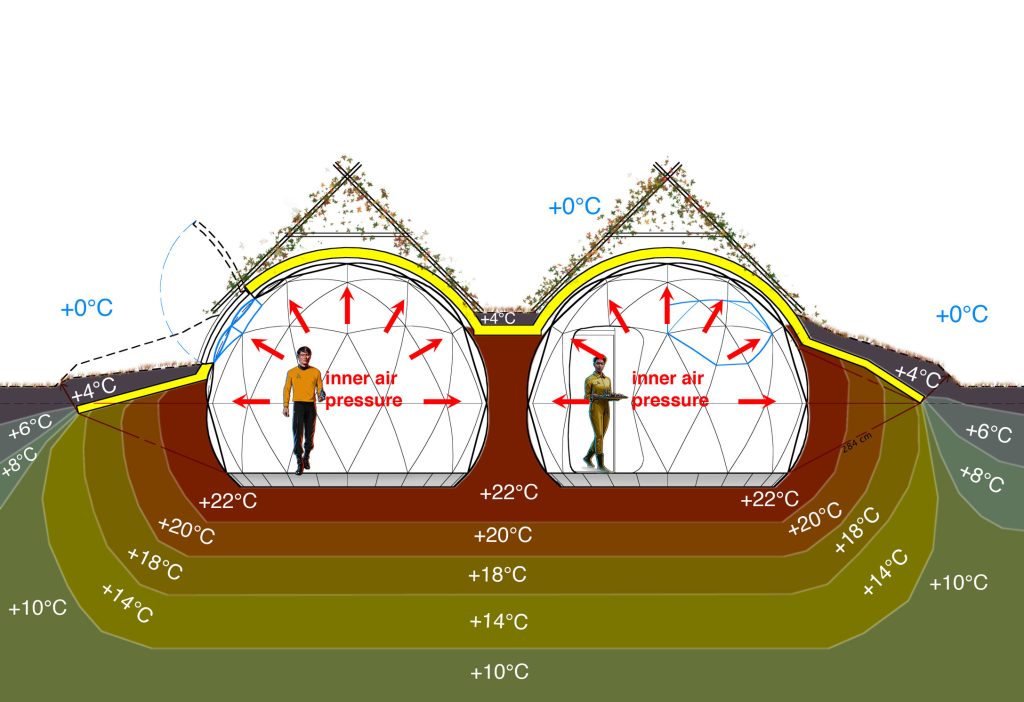

PNEUMO PLANET consists of inflatable structures that form room modules that can be connected to complete residential homes. They are partially or fully buried in the ground in order to benefit from the thermal properties of the soil. Only the inner air-pressure holds against the external earth pressure.

These ultralight inflatable modules are inexpensive to produce and quickly to install. They require a minimum of material only and therefore very little primary energy in production.

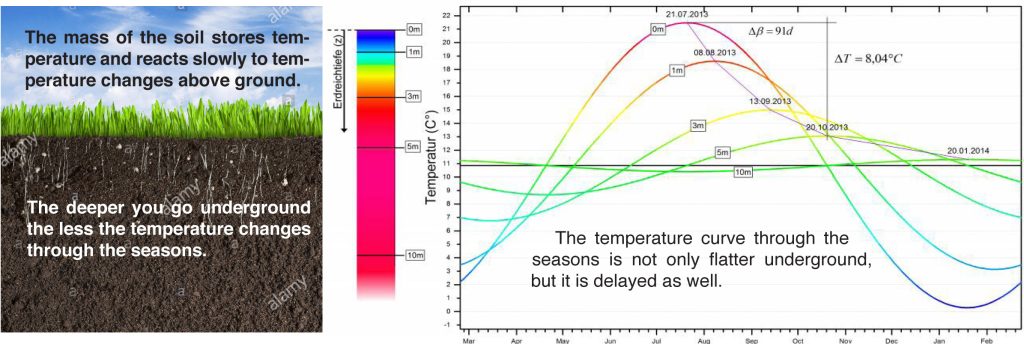

The surrounding local soil is a free gift from nature and takes on the functions that thick walls would otherwise take on. It not only operates as a heat insulation, but as a heat storage as well.

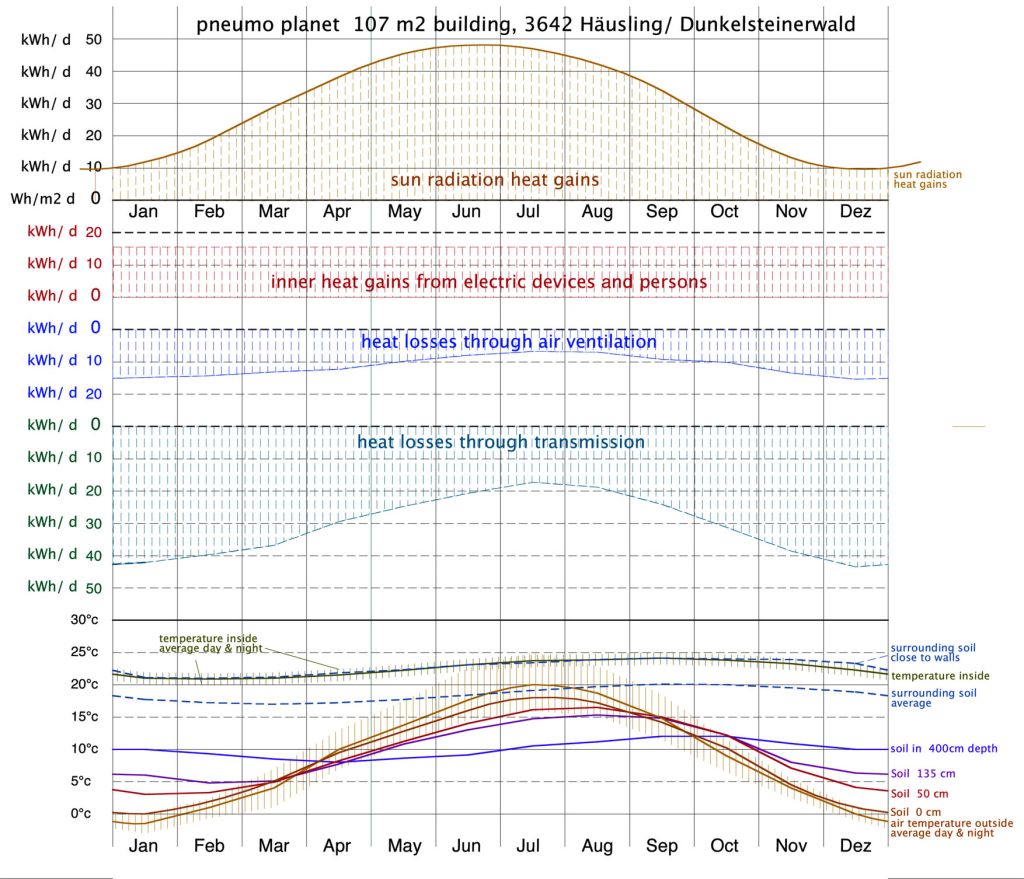

The deeper the earth layer, the smaller are the temperature fluctuations between winter and summer and the more the peaks of the annual temperature curve are shifted backwards in time compared to the air temperature.

Through south oriented windows sunlight can pass and heat up the interior space. The excessive heat is absorbed and stored by the surrounding soil. This way, the mostly constant temperature of the soil in these deep layers is increased to a level of around 20°C, matching the required inside room temperature.

A horizontal heat insulation on top helps to reduce heat losses from the soil to the air.

- By carefully optimizing the size and orientation of the windows and the heat insulation, we can provide an optimal and mostly constant interior temperature without any additional energy requirement for heating or cooling. Although we do need thermal insulation, it is considerably less of it than in a building of conventional construction with walls and ceilings consisting of concrete and EPS insulation.

Not only are the rooms modular, but each room module consists of modular cushions in a triangular grid constellation. The same type of cushions can form different room modules of different size and shape.

The reasons for the cushion structure are following:

- The heat transfer from indoor to the soil is delayed.

- The cushions form a soft smooth surface inside

- The double layered membrane keeps the structure airtight even when one layer is punctured.

- The location of a puncture can easily be detected. When the outer membrane is punctured the inner membrane layer of the cushion is pressed outside, if the inner layer is punctured, it hangs down loosely.

The inner air pressure is provided by two sets of side channel blowers with an automatic pressure switch. The blower only operates when the air pressure drops under the required level. Generally, the structure is airtight, but air loss still happens went people pass through the air lock and from the required air ventilation.

Since we want to make sure that the structure remains inflated under any conditions, we provide two independently operating blowers for redundancy.

Additionally, the blowers are not sourced by electricity from the grid only, but from a battery as well. That battery is charged from photovoltaic panels (that would be installed anyway in our days). In case the photovoltaic system fails, we additionally provide a petrol-engine powered generator.

By only having the sidewalls and the floor covered with soil, while the roof is covered by a light thermal insulation only, even a collapse of the structure would not be critical for the safety of the residents.

Membrane cutting panels for production of an inflatable room module:

The structure consists of two membrane layers. The outer layer is double sided TPU- coated polyamidfrabric. The inner layer is one side TP coated fabric, with the fabric inside.

So the inner surface of formed by smooth soft inflatable cushions of polyamide fabric.